THREE DIFFERENT SOLUTIONS FOR PLASTICIZER APPLICATIONS

The plasticizer industry is wide and includes many different applications, such as PVC wallcoverings, PVC flooring, PVC fences, etc.

One of the main problems of the plasticizer industry is the emission of sub-micron mists (DOP).

How can AWS help with the removal of these pollutants?

In this article you will find three different cases of plasticizer industries that relied on AWS FiberwindTM candles and AWS FiberwindTM complete plant as the best solution for the complete removal of sub-micron mists and other pollutants referred to this specific industry.

01) APPLICATION:

PRODUCTION OF SYNTHETIC LEATHER

Technical solution:

The customer asked for a repack of existing candle filters.

Screens and flanges supplied by the customer

In this case the screens have to be perfectly cleaned, the exhaust old fiber must be removed by the client to allow us to repack the filter.

Filtering media

The candle is made of special glass fiber rope filtering media, where the entire filtration process happens.

Advantages of candle refurbishment:

Cost saving: no need to buy new external cages Environmentally friendly: less waste (of cages steel and wooden packings)

02) APPLICATION:

PRODUCTION PLANTS FOR PVC FENCES AND NETS

Technical solution:

AWS in this case supplied brand new FiberwindTM filters:

Screens and flanges supplied by the customer

Screens and flanges are supplied in carbon steel since this type of material is recommended in case of presence of DOP (that is quite similar to oil mist when liquid).

The plane top flange is fully adaptable to any type of tower.

Filtering media

The candle filter is made of special glass fiber rope filtering media.

AWS ensure a long-lasting product, made with quality material and proper openings to improve the strength of the structure.

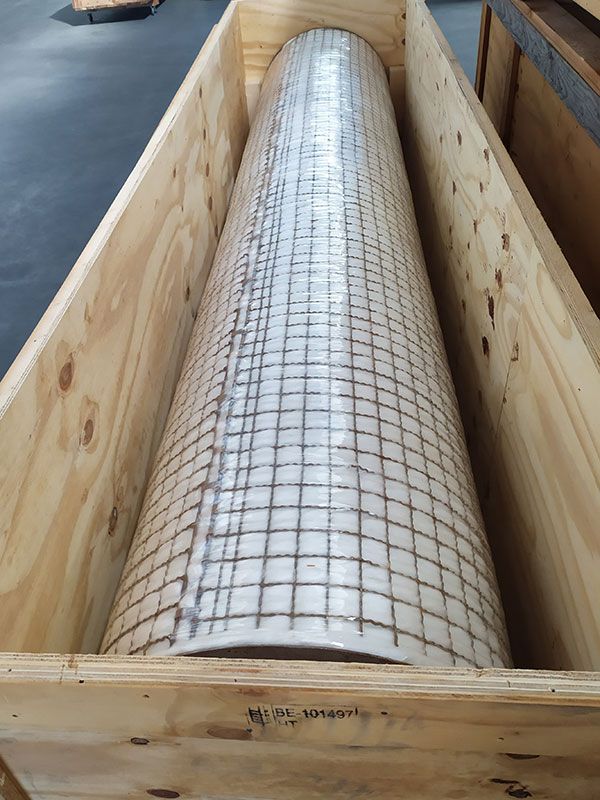

The wooden box is definitely the best way to safely transport the filter to the customer’s site.

03) APPLICATION:

PRODUCTION OF PVC FENCES AND NETS

Technical solution:

AWS supplied a complete FiberwindTM plant

In a typical FIBERWIND plant the raw gas loaden with oil mists, aerosol and solids enters first a set of prefilters where the solids and the bigger liquid droplets are removed.

The air flow passes through the heat exchangers where the temperature is cooled from 120°C down to 40°C max, in order to allow DOP become liquid and be removed in the next stage.

The air is then carried on to the filtration chamber which is equipped with FIBERWIND type BM coalescing filters.