AWS PILOT PLANTS IN FERTILIZER APPLICATIONS

Fertilizer plants have to cope with several issues regarding the emission levels, for example emissions related to dust & ammonia, which may require different types of technical solutions and products.

How can AWS help with the removal of pollutants and emissions in fertilizer plants? The ElectrocleanTM WESP technology is our best reliable solution in this case for the removal of sub-micronic dust particles, but what if our customer is not ready to invest in such a complete and decisive technology?

AWS Pilot plants are specifically made to be installed downstream the existing plants, in order to provide an immediate service without influencing or interrupting the production process of the existing plant.

Our pilot package includes the support of one of our expert technicians or even remote assistance with our VR Helmet technology.

Keep reading and find out how to choose the best solution for the removal of pollutants in the fertilizer industry.

APPLICATION: FERTILIZER

Process conditions

-

170 m3/h flowrate, max flowrate 350 m3/h

-

Temperature: 55 to 65°C

-

Dust limit: 10 mg/ m3

Technical solution

-

Small WESP pilot plant with 1 collecting tube

The test ended with brilliant results

The inlet dust concentration was 155 mg/Nm3 dry, the outlet dust concentration after the test period was 3 mg/Nm3 (approximate an overall efficiency removal of 98%).

The customer was satisfied and after some time the company decided to adopt the WESP complete system to solve the dust problems downstream the production process. In the photos here below, you can see the small pilot plant at the beginning of the project, installed on site, and the final WESP completed and successfully working.

APPLICATION: FERTILIZER

Process conditions

-

Flowrate: Max 2.500 m3/h

-

Temperature: 25°C (flow gas inlet) / 90 to 100°C (exhaust gas inlet)

-

Dust limit: 30 mg/Nm3

Technical solution

-

Large WESP pilot plant with 7 collecting tubes

Our customer needed to test the efficiency of the WESP technology to remove Ammonium nitrate, Calcium Ammonium nitrate (CAN) & NS products.

The actual dust limit was 30 mg/Nm3 but it is possible that the limit could lower to 10-20 mg/Nm3 in the next few years.

Thanks to our pilot plant the dust emissions at the outlet already satisfied the customer’s need: 5 – 10 mg/Nm3 with inlet dust load of 35 – 70 mg/Nm3

In the photos here below:

Large pilot plant loading on the truck, and pilot plant installed on site!

APPLICATION: FERTILIZER

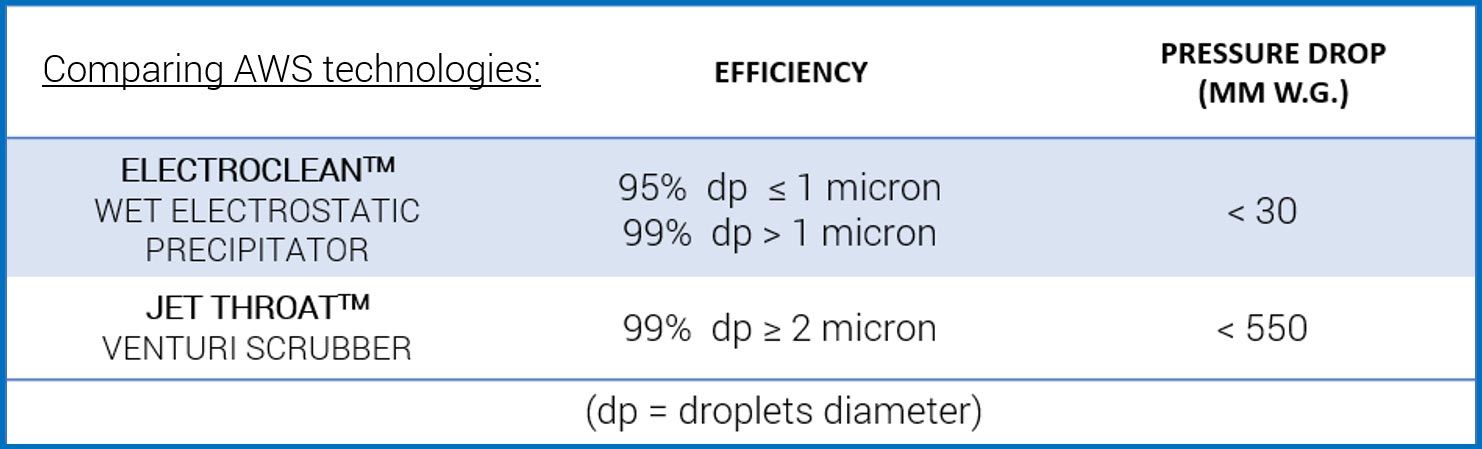

This request is foreseeable when discussing about emission control in fertilizer industry. We installed several Wet Scrubbers and they still work fine, but there is no comparison with the Wet ESP technology, here’s some data:

The main advantage of the Venturi scrubber is that it is a relatively small technology, simple to operate and the initial investment is far less comparing to a WESP.

Moreover, the Venturi can handle sticky, flammable and corrosive PM.

One of the biggest disadvantages is the high energy cost. The system can manage low gas flow rates and the pressure drop is higher. Last but not least: the Venturi may cause downstream corrosion and visible plume, together with production of sludge at the end of the process.

The wet scrubber may seem an easy and good choice at first, but always remember to check the many facets of a project. We are always here to help you with this, don’t hesitate to contact us for more info!

ELECTROCLEANTM Wet Electrostatic Precipitator

JET THROATTM Venturi Scrubber