AIR POLLUTION CONTROL SYSTEMS

Wet ElectroStatic Precipitator (WESP)

ELECTROCLEAN™

Wet ESP

Wet Electrostatic Precipitators (WESP) offer efficient emissions control for sub-micron particulate, heavy metals, acid mist, oil mist. The WESP is recommended because of its proven performance, compactness, robust design, automatic operation, and low operating costs.

Fields of application:

- Textile processing

- Veneer and particle board dryers

- Phosphorous furnace emission

- Silicon manufacturing

- Hazardous waste incinerator

- Biomass drying

- Sulphuric acid plants

- Food processing industry

POLLUTANTS REMOVED:

- HCl, HBr, HF, H2S, NH3

- SO2, SO3, SiO2

- Oil mist, sub-micron particulate, VOCs

- Aldehyds, phenol

PROCESS DESCRIPTION

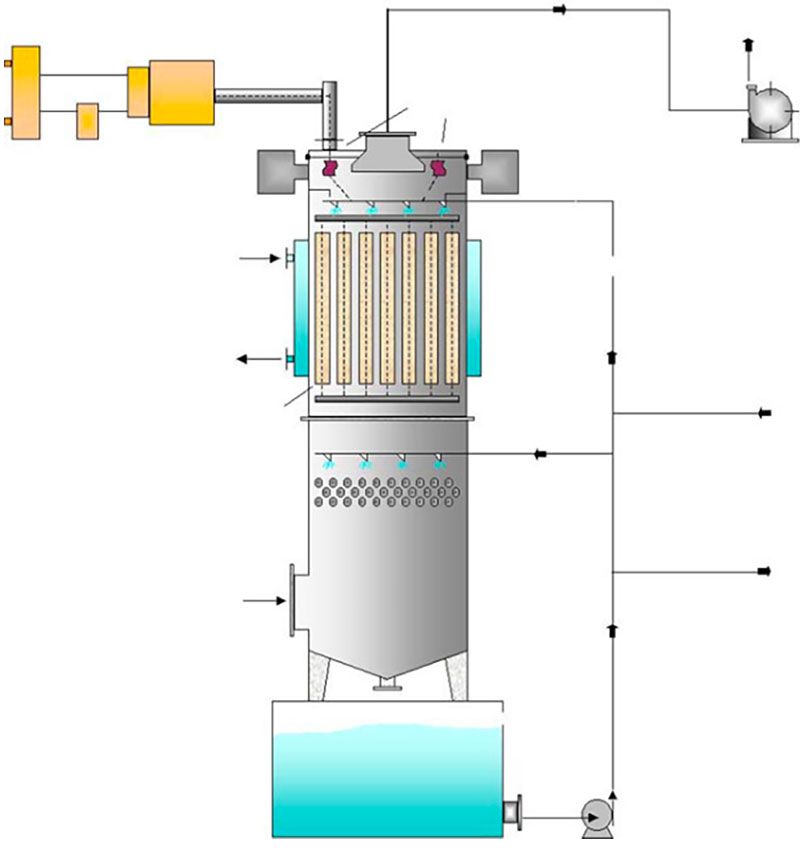

Scrubber section

Hot contaminated gas from the production lines are cooled to full saturation and pre-cleaned from all particles larger than 2 microns in a special un-clogging scrubber.

The scrubber creates a turbulent layer of fine mist which accomplishes the mass transfer of toxic gases and the capture of large particles onto the mist bubbles.

The turbulent layer provides good mass transfer and offers efficient gas cooling below adiabatic saturation together with good absorption of soluble compounds.

Collector section

In the vertical design, the evenly distributed saturated gas flows upward through the electrostatic section of the WESP. An ionizing electrode runs down the centre of each tube. A strong electrical field is generated between the central discharge electrode and the collecting tube.

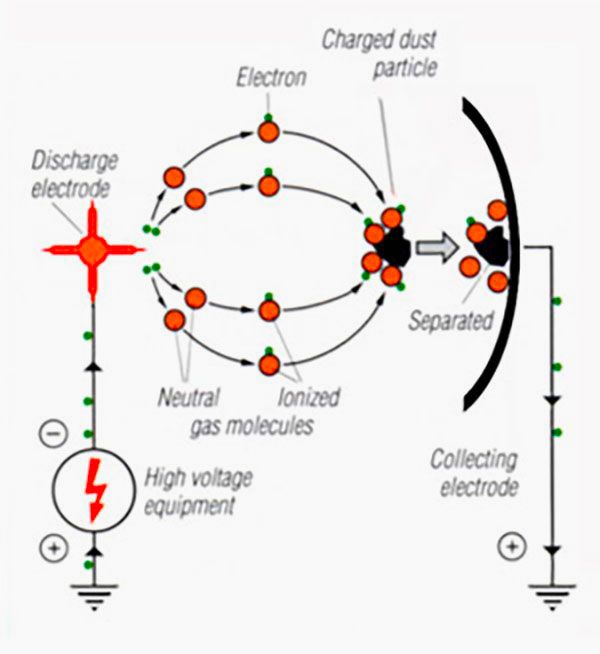

Electrons are emitted from the discharge electrodes which are charged with a rectified negative high voltage. Due to the high voltage difference, these electrons migrate towards the collecting electrodes: as particles pass through the gap between the discharge electrodes and the tube walls, they are intercepted by negatively charged gas molecules. These negatively charged gas molecules or negative ions accumulate on the particles surface and become fully saturated with negative charge.

As the gas with charged particles passes up the tube, it enters the collection section where there are strong repelling forces. The strong electrical field causes the charged particles and entrained droplets to migrate to the inner surfaces of the tube and consequently to be removed from the gas flow.