AWS FIBERWIND MIST ELIMINATORS

INTERESTING CASES FROM THE PAST YEAR

If you know AWS Corporation, you know our FiberwindTM candle filters very well.

The FiberwindTM type of mist eliminators are one of our best-sellers: hundreds of customers worldwide are currently filtering flue gases and pollutants thanks to our filters.

This article presents few interesting examples of candles supplies completed during year 2021, check it out!

APPLICATION: ATS PRODUCTION UNIT

Process conditions

-

Gas flowrate: approx. 5.000 Am3/h

-

Temperature: approx. 40 °C

Technical solution

-

FIBERWINDTM filter with carbon fiberbed

The customer is a well know chemical industry producing many different products.

In this case our candle filters have to be installed in a ATS production unit (Ammonium Thiosulphate).

The ATS is made from the mixture of liquid elemental Sulfur and Ammonia.

Moreover, the plant produces Sulfur Dioxide (SO2) and Ammonium Bisulfite (ABS) as well.

Our Fiberwind candle mist eliminators have been installed in an absorption column downstream the production plant in order to remove the reintrained mist from SO2 scrubber before stack.

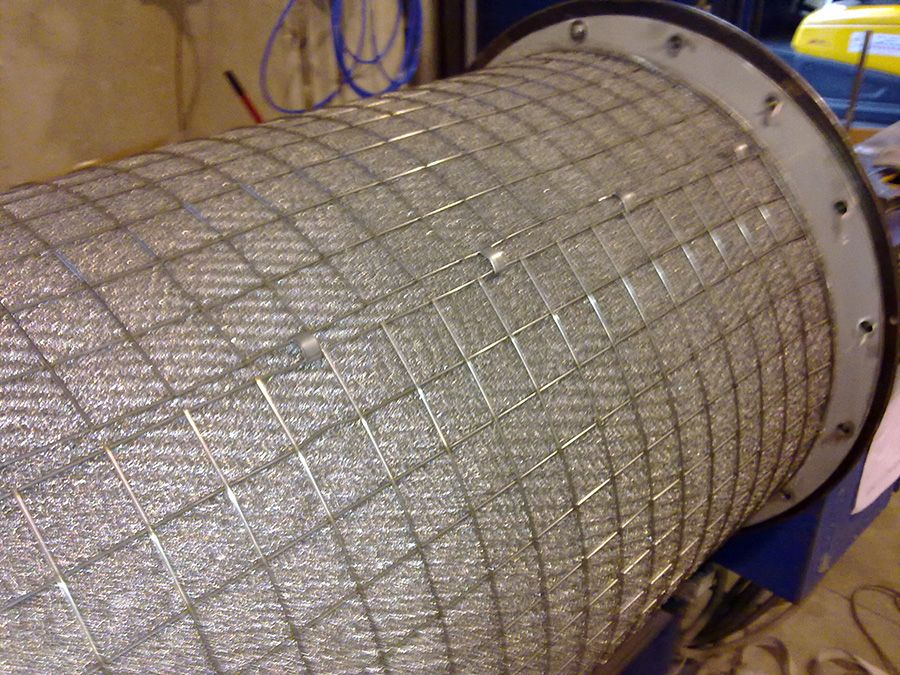

This specific chemical environment required special filters: Brownian mist eliminators with SS316L outer screens & carbon mattress to avoid the corrosion of the filtering media in an alkali environment.

The customer confirmed the positive results after the installation of the set of AWS Fiberwind candles:

- Transparent plume out of the stack: before the installation they had white plume instead;

- Downstream issues solved, for example: no crystallization of the oxygen analyzer;

- The final emission tests also confirmed the performance promised during the offer stage.

APPLICATION: PLASTICIZER PRODUCTION PLANT

Process conditions

-

Gas flowrate: 25.000 Am3/h

-

Temperature: 40°C

What needs to be filtered:

Technical solution

Repack of FIBERWINDTM filters with special glass fiber

The plasticizer industry often requires candle filters to collect organic sub-micron mists (DOP).

Our customer already purchased new filters time ago, and when needed, they send back the exhausted filters to get repacked with new filter media.

This process is required after about 4 years.

The exhausted mist eliminator must be cleaned and discharged from the old fiber. The empty cages are then carried at our warehouse in Cologno to proceed with the

repack.

What are the advantages of refurbished filters?

Cost saving: no need to buy new external cages.

Time saving: we only need the time to repack the filter with new media: just for example: a set of 12 filters usually take less than 2 weeks.

Environmentally friendly: less waste - of cages steel and wooden packings.

APPLICATION: SULPHURIC ACID PLANT

Process conditions

-

Gas flowrate: 40.000 Nm3/h

-

Temperature: 75°C

Technical solution:

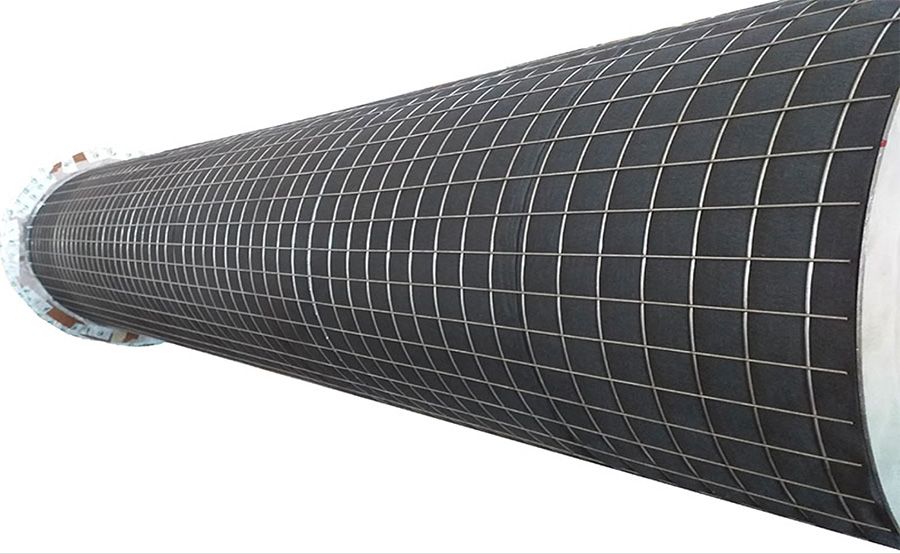

FiberwindTM IMPACT filters with special mattress fiberbed and SS316L external cage.

We are used to see Brownian movement candles, but don’t forget that we can always supply IMPACT candles as well, which are more suitable in case mist particles are not so fine, as in this case.

Our Fiberwind IM candles are usually required for:

- Sulphuric acid plants: for drying towers;

- Sulphonation plants: between SO3 generators and sulphonation reactors;

- Mist removal in compressed CO2.

In this case the IM filters have been installed in a Drying Tower of a Sulphuric acid industry.