WHY ARE LANCES AND NOZZLES SO SPECIAL?

Why should you choose AWS Atospray system?

Discover the features of these little but powerful components!

AWS ATOSPRAY TECHNOLOGY:

AWS supply a wide variety of high-tech solutions to cope with pollution-control requirements in several industries.

In order to satisfy the different needs of our customers, we are always looking for versatile and adaptable solutions.

This is where the nozzle comes.

Our atomization dual-phase spray nozzles are widely used to inject compressed air with water or reagents, based on which result we want to reach: temperature control, acid absorption, SO2 absorption, NOX reduction, combustion applications.

The internal mixing chamber is the essential feature of our nozzles: its shape perfectly combines atomized air and liquid and cause the acceleration of the mixture. The result is an extremely fine atomization of droplets.

Let’s find out how nozzles can be integrated into different applications!

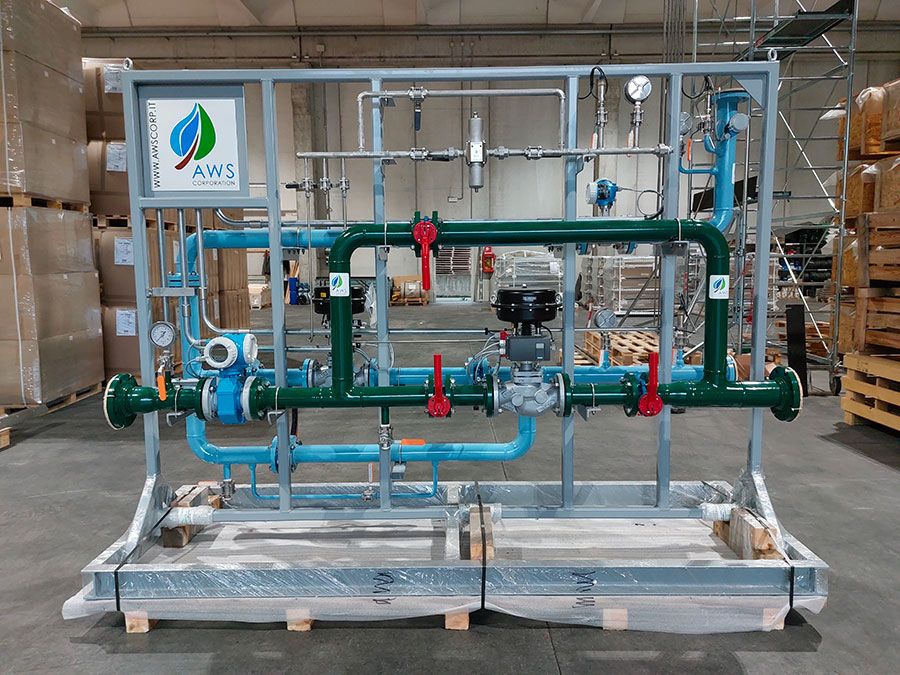

ECS Evaporative Cooling System

ECS Solution

Evaporative Cooling systems are fundamental to keep the stream temperature under control.

Atomization dual-phase nozzles are the essential feature of the ECS, and thanks to the innovative technology of these components, we can easily reach the following advantages:

- Accurate temperature control;

- Fast evaporation;

- Protection of downstream equipment;

- No water carryover;

- No dry dust discharge;

- Minimal build up on the sidewalls;

- Low pressure drop;

- Low maintenance.

Examples of ECS Applications:

Cement: Gas Conditioning Tower, Bypass Tower, Kiln End Sprays, Clinker Cooler

Steel: Electric Arc Furnace, Basic Oxygen Furnace

Non-Ferrous: Copper or Nickel Converter Off gas Cooling

Petrochemical: Waste Heat Recovery Unit, Cat-cracker

Organic: Surrogate Cooling for Dryers

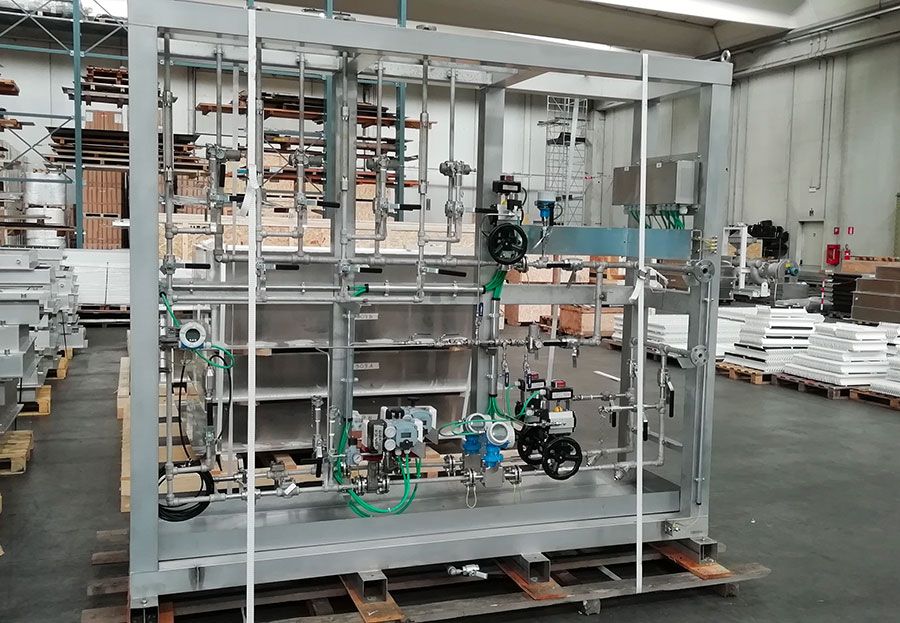

SCR – Selective catalyst reduction – injection lances

Urea injection

Selective Catalyst Reduction (SCR) system is a post-combustion emissions control technology for reducing NO and NO2 (NOX) through a catalyst coming into contact with a chemical reagent.

In this specific case we supplied just the atomization injection lances at service of the SCR system, but we usually supply dosing-pump skids as well.

AWS atomization systems ensure extremely fine atomization of the acqueos ammonia and urea into the flue-gas.

A series of chemical reactions between Urea (or Ammonia) and NOx results in a reduction of NOx with generation of:

IN CASE OF UREA: N2 + CO2 + water

IN CASE OF AMMONIA: N2 + water

Examples of SCR Applications:

Steel: Flue gas from coking, sintering, pelletizing machines

Incinerators: Waste, biomass, waste-liquid incineration

Construction industry: Cement, glass, ceramic, lime, refractories industries

Metal smelting

Chemical & Petrochemical exhaust gases

SNCR - Selective Non Catalytic Reduction

Ammonia Injection System

The SNCR system is used to remove NOx from a gas stream by means of atomization dual-phase nozzles, which are installed in a complete spraying system, injecting Urea or Ammonia directly in the combustion chamber, without any catalyst.

Then, you will need to install an efficient ammonia injection system too: AWS lances and nozzles ensure an extremely fine atomization of the ammonia into the flue-gas.

SNCR Main Features:

- NOx gas control system and pollution reduction;

- Low reagent consumption;

- Low cost reagent (aqueous Ammonia or Urea);

- Low pressure drop;

- High efficiency and control for Ammonia slip.

Applications:

Combustion Chamber offgas

Biomass & Power generation boilers

Cement mills