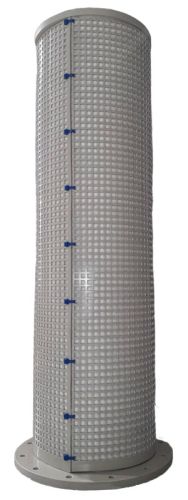

FIBERWIND CANDLE FILTERS

FIBERWIND CANDLE FILTERS

100% CUSTOMIZABLE!

FIND THE RIGHT AWS SOLUTION

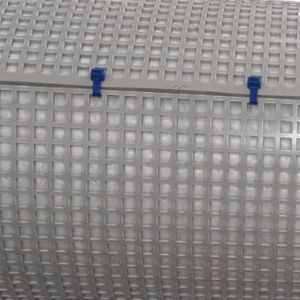

EXTERNAL CAGE:

INOX ALLOYS (316L, 304L)

SUITABLE FOR:

- Environment with high concentration of H2SO4 (i.e. drying towers, SO3 scrubber section)

- Sulphonation plants, between SO3 generators and sulphonation reactors

- Mist removal in compressed CO2

- Filtration of Hydrogen gas with NaOH

FRP & GRP

SUITABLE FOR:

- Environment with low concentration of acid

- Aggressive environment

- Wet-chlorine application

POLYPROPYLENE

SUITABLE FOR:

- Basic environment

- Chloro-Alkali hydrogen lines

PVDF / TEFLON

SUITABLE FOR:

- Alkali wet-chlorine application

TITANIUM

SUITABLE FOR:

- Alkali wet-chlorine line, in order to remove salts

- Filtration of chlorine gas containing corrosive salts and moisture

- Good alternative of FRP cages

IM CONFIGURATION

SUITABLE FOR:

- IM – impact – candles are usually requested when the particles to be collected are above 1 micron

INTERNAL FILTERING MEDIA:

GLASS FIBER

- Our most used filtering media

- Ensures no turndown problems

- 100% collection for all particles over 3 microns

SPECIAL GLASS FIBER

- Rope made of fine fibers

- The most efficient and coalescing filtering media

- Suitable for all applications, except for alkali environment

GX

- Made of different layers to facilitate the drainage of liquid

- Excellent reduction of pressure drop (-30%)

- Suitable for high-velocity gases

- Usually requested for SO3 scrubber sections of sulphuric acid industries

POLYPROPYLENE

- High reliability over time

- Fiberbed with excellent stability

- Usually requested by alkali-environment industries

CARBON

- Suitable for alkali-environment to avoid corrosion

- Filtration of NaOH mist from hydrogen gas

- Long-lasting candle life cycle

- Usually requested by industries with fluorides, high PH, or steam applications

TEFLON

- Usually requested by fertilizer industries because of the high risk of corrosion, due to basic environment

SPECIAL CONFIGURATIONS:

DOUBLE CANDLES

- Larger filtering area

- Lower pressure drop

- Suggested in case of higher flowrate due to the increase of plant production.

- No need to change the diameter of the tower: replacing single-candles with double-candles could be the perfect solution

FIBERWIND PLANT

- Our Fiberwind complete plants are usually installed downstream the heat exchangers: during the cooling process, the raw gas becomes a submicronic mist, formed by condensation

- The air is then carries on to the filtration chamber which is equipped with our Fiberwind filters

- The submicronic mist is then separated from the gas stream thanks to our Fiberwind candle filters